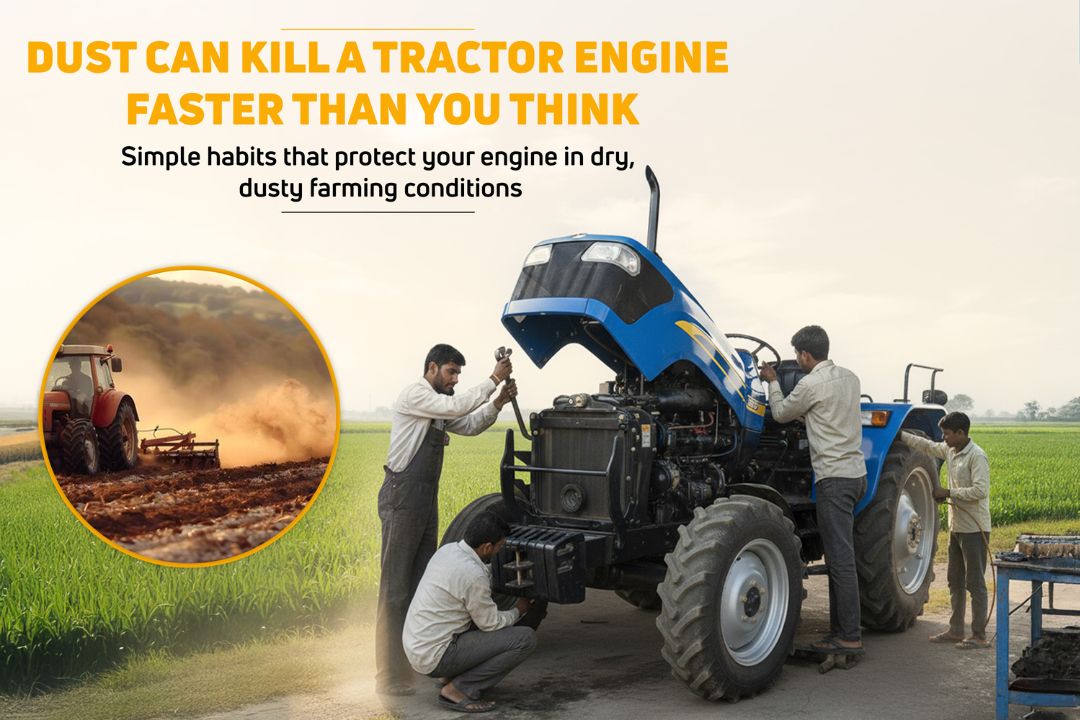

How to Increase the Lifespan of Your Tractor Engine in Dusty Farming Conditions

If you farm in dry regions, you already know that dust gets everywhere. It settles on crops, tools and especially on tractors. Over time, that fine dust becomes the biggest reason engines lose power, overheat or fail earlier than they should. Most engine damage in dusty farming doesn’t happen suddenly because it builds up slowly, day after day.

The key to a long-lasting tractor engine in dusty conditions isn’t complicated maintenance. It is paying attention to a few dust-related habits and not ignoring small signs.

Start with the Air, Not the Engine

Dust enters the engine through the air first. That’s why the air filter matters more in dry farming than almost anything else. In dusty fields, checking the air filter once a week is often not enough. During peak work it may need inspection every day. If the filter looks grey or packed with dust, you should clean it gently or replace it. Running a tractor even for a few hours with a choked filter forces dust toward the engine and reduces combustion efficiency.

Many farmers underestimate this step, but a neglected air filter shortens engine life faster than most mechanical issues.

Oil Gets Dirty Faster in Dusty Fields

Dust doesn’t just stay outside, it eventually mixes with engine oil. When oil carries fine dust particles, it loses its ability to protect internal parts properly.

In dry conditions, oil change intervals should be shorter. Even if the manual allows longer gaps, changing oil closer to 100 hours is safer in dusty regions. Always check oil levels before starting work. Low or dirty oil increases friction, heat and long-term wear.

Dust Blocks Cooling More Than You Think

Radiators clog quietly, and a thin layer of dust on radiator fins is enough to reduce cooling efficiency, especially during long hours of fieldwork.

Make it a habit to clean the radiator screen and fins regularly. Many overheating problems blamed on coolant are actually caused by blocked airflow. Coolant can’t do its job if dust prevents heat from escaping.

Cleaning Is Not Optional in Dry Farming

Leaving the tractor dirty after work might save time today, but it costs engine life tomorrow. Dust builds up around belts, pulleys, joints and the engine block itself.

A quick clean around the engine area, air intake and radiator after work helps prevent dust from settling deeper overnight. It also makes it easier to notice leaks or loose parts early.

Lubrication Reduces Dust Damage

Dust acts like sand on moving parts. Grease and lubrication reduce that grinding effect. In dusty conditions, joints and linkages dry out faster. Following the lubrication schedule and sometimes doing it a little earlier helps protect components that dust constantly attacks.

Where You Park Matters

Parking a tractor in the open means it collects dust even when it’s not working. Overnight dust settles into filters, wiring and engine bays. If a shed isn’t available, covering the tractor properly still helps. Less dust at rest means less dust entering the engine the next day.

Conclusion

Dusty farming conditions don’t automatically mean shorter engine life, but neglect does. Clean air filters, timely oil changes, clear radiators and regular cleaning make a bigger difference than most upgrades. In dry fields, engine longevity depends more on daily habits than on brand or horsepower.

Motorfloor takeaway: In dusty farms, engines fail slowly, not suddenly. A few minutes spent controlling dust can add years to your tractor’s working life.