Tractor Tyres Explained: Choosing the Right Tyres for Indian Soil Types

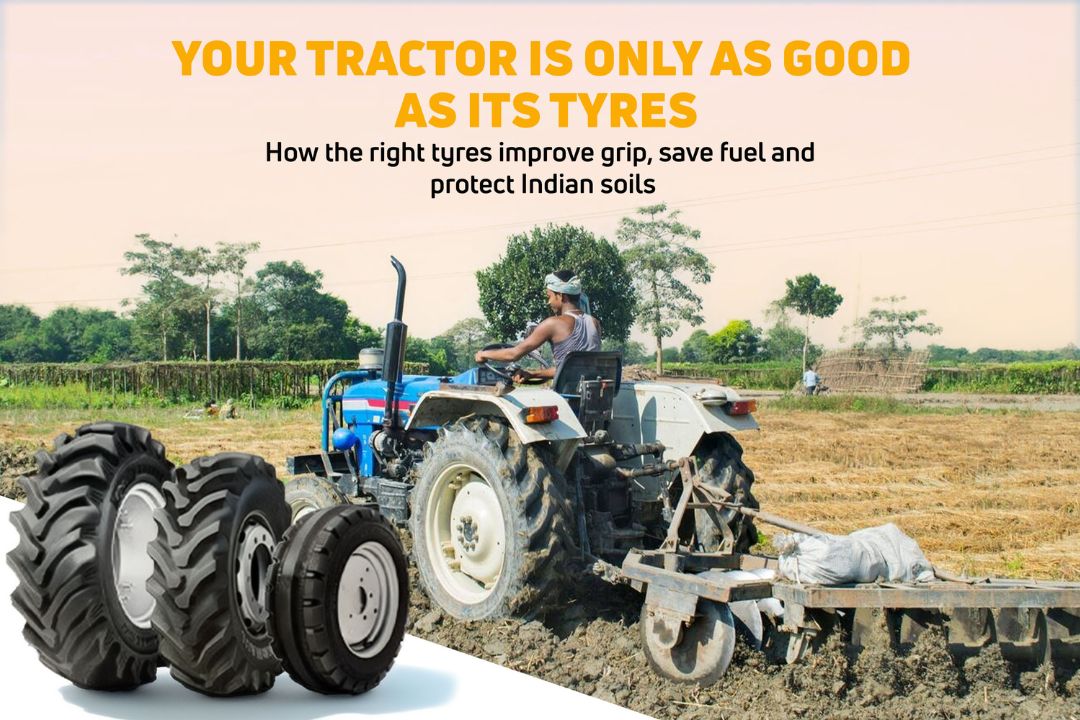

Most farmers spend weeks deciding on a tractor, but barely a few minutes thinking about tyres. That’s understandable because tyres don’t look exciting. But in day-to-day farming, tyres decide how much of your tractor’s power actually reaches the soil.

In India, this matters more than people realise. Soil can change from sandy to clay-heavy within a few kilometres. A tyre that works well in one village can struggle badly in another.

Why Tyres Make or Break Field Performance

When tyres aren’t suited to the soil, the tractor starts slipping. Slippage means wasted diesel, uneven fieldwork and more strain on the engine. Over time, it also compacts soil, which quietly reduces crop yield.

Good tyres don’t just improve grip. They protect soil structure, reduce fuel use and make long working hours less tiring for both tractor and operator.

Before Soil Type, Think Basics

Tread design decides how well tyres bite into soil and clean themselves. Width affects how weight spreads, for example, narrow tyres dig in, wider ones float better. Radial tyres flex more and usually save fuel, while bias tyres are tougher and cheaper for rough use. And load rating must always match your implements, this part is often ignored.

Matching Tyres to Indian Soil

Sandy soil looks easy but causes problems fast. Narrow tyres sink and dig holes. Wider tyres, especially flotation types, spread weight better. Radial tyres help reduce rolling resistance and save fuel here.

Clay soil is the opposite. Wet clay sticks to tyres and blocks tread gaps. Dry clay turns rock-hard. Deep-lug agricultural tyres (R-1 or R-1W) work best because they clean themselves better. Correct air pressure is critical but too much pressure compacts the soil badly.

Loamy soil is forgiving, which is why efficiency matters more than brute grip. Radial tyres with balanced tread patterns work well for both field and road use, especially on farms that do mixed operations.

Rocky or hard soil destroys weak tyres quickly. Bias-ply tyres survive better here because of stronger sidewalls. Reinforced radial tyres also work, but only if puncture checks are done regularly.

Wet or marshy fields, especially paddy land need special attention. Paddy tyres with aggressive lug patterns are designed to grip mud without constant slipping. Wider tyres reduce sinking and rut formation.

Hilly or sloped land brings safety into the picture. Wider tyres improve stability and deeper lugs improve grip. Incorrect tyre pressure on slopes is risky, this is where small mistakes matter.

Radial vs Bias

Radial tyres are better for fuel efficiency, traction, and soil health. Bias tyres are cheaper, tougher, and easier to live with in rough terrain. Many farmers actually use both depending on field conditions.

Conclusion

Tyres don’t add horsepower, but they decide how well you use it. The right tyre doesn’t just move the tractor forward; it protects the soil that feeds your crops. In farming, that connection matters more than most people think.

Motorfloor takeaway: Before upgrading your tractor or implements, look at your tyres. The right tyre choice can save fuel, protect soil and quietly improve every season’s work.